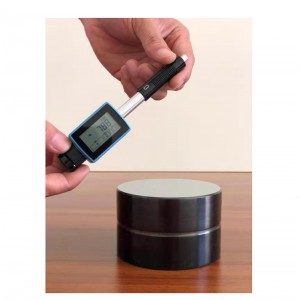

Mai Gwajin Taurin Leeb Mai Ɗauki na HL150

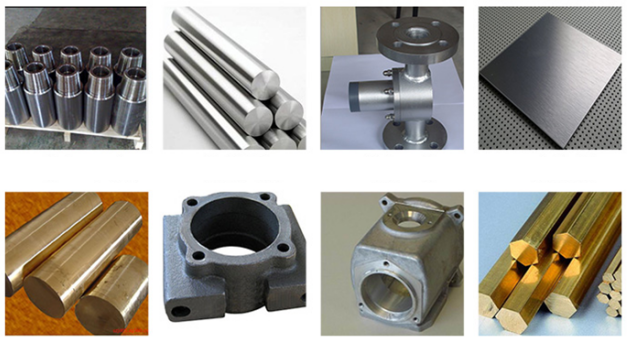

Ramin mutu na molds

Bearings da sauran sassa

Binciken gazawar jirgin ruwa mai matsin lamba, janareta mai tururi da sauran kayan aiki

Kayan aiki mai nauyi

Injinan da aka sanya da kuma sassan da aka haɗa har abada.

Gwajin saman ƙaramin sarari mai rami

Bukatun rikodin asali na hukuma don sakamakon gwaji

Gano kayan aiki a cikin ma'ajiyar kayan ƙarfe

Gwaji mai sauri a wurare masu yawa da kuma wurare masu aunawa da yawa don manyan ayyuka

An ambaci ƙimar kuzari a cikin sashin tauri na HL kuma an ƙididdige shi ne ta hanyar kwatanta saurin tasirin da dawowar ƙarfin jikin tasirin. Yana dawowa da sauri daga samfuran da suka fi tauri fiye da waɗanda suka fi laushi, wanda ke haifar da ƙimar kuzari mafi girma wanda aka bayyana a matsayin 1000×Vr/Vi.

HL=1000×Vr/ Vi

Ina:

HL - Darajar taurin Leeb

Vr - Saurin sake dawowa na jikin tasirin

Vi - Saurin tasirin jikin tasirin

Zafin aiki:-10℃~+50℃;

Zafin ajiya:-30℃~+60℃

Danshin da ya dace: ≤90%;

Ya kamata muhallin da ke kewaye ya guji girgiza, ƙarfin filin maganadisu, matsakaicin lalata da ƙura mai nauyi.

| Kewayon aunawa | (170~960)HLD |

| Alkiblar tasiri | a tsaye zuwa ƙasa, mai karkata, a kwance, mai karkata, a tsaye sama, gano ta atomatik |

| Kuskure | Na'urar tasiri D:±6HLD |

| Maimaitawa | Na'urar tasiri D:±6HLD |

| Kayan Aiki | Karfe da simintin ƙarfe, ƙarfen kayan aikin sanyi, Bakin ƙarfe, ƙarfe mai launin toka, ƙarfe mai simintin ƙarfe, ƙarfe mai simintin ƙarfe |

| Sikelin Tauri | HL, HB, HRB, HRC, HRA, HV, HS |

| Min zurfin Layer mai tauri | D≥0.8mm;C≥0.2mm |

| Allon Nuni | Babban LCD na Kashi Mai Bambanci |

| Ajiya | har zuwa ƙungiyoyi 100 (Dangane da matsakaicin lokaci 32~1) |

| Daidaitawa | Daidaita maki ɗaya |

| Buga bayanai | Haɗa PC don bugawa |

| Ƙarfin wutar lantarki na aiki | 3.7V (Batirin lithium polymer da aka gina a ciki) |

| Tushen wutan lantarki | 5V/500mA; sake caji na tsawon awanni 2.5~3.5 |

| Lokacin jiran aiki | Kimanin awanni 200 (ba tare da hasken baya ba) |

| Sadarwar sadarwa | USB1.1 |

| Harshen aiki | 'Yan China |

| Meterial na harsashi | Filastik injiniyan ABS |

| Girma | 148mm × 33mm × 28mm |

| Jimlar nauyi | 4.0KG |

| Manhajar kwamfuta | Ee |

1 Fara-shiga

Danna maɓallin wuta don kunna kayan aikin. Sannan kayan aikin zai fara aiki.

2 Ana lodawa

Tura bututun ɗaukar kaya zuwa ƙasa har sai an ji taɓawa. Sannan a bar shi ya koma a hankali zuwa wurin farawa ko ta amfani da wata hanya ta kulle jikin tasirin.

3 Wuri

Danna zoben da ke tallafawa na'urar tasirin da ƙarfi a saman samfurin, alkiblar tasirin ya kamata ta kasance a tsaye zuwa saman gwaji.

Gwaji 4

- Danna maɓallin sakin da ke gefen na'urar don gwadawa. Samfurin da na'urar tasirin da kuma

Ana buƙatar duk mai aiki ya kasance mai ƙarfi yanzu. Alkiblar aikin ya kamata ta wuce axis na'urar tasirin.

-Kowane yanki na auna samfurin yawanci yana buƙatar aikin gwaji sau 3 zuwa 5. Yaduwar bayanan sakamakon bai kamata ya zama dole ba

fiye da matsakaicin ƙima ± 15HL.

- Nisa tsakanin duk wani wurin tasiri guda biyu ko daga tsakiyar kowane wurin tasiri zuwa gefen samfurin gwaji

ya kamata ya yi daidai da ƙa'idar Tebur 4-1.

-Idan ana son samun daidaiton canji daga darajar taurin Leeb zuwa wani darajar taurin, ana buƙatar gwajin bambanci don samun

dangantakar juyawa don kayan musamman. Yi amfani da na'urar gwajin taurin Leeb mai cancantar dubawa da kuma wanda ya dace.

na'urar gwada tauri don gwadawa a samfurin iri ɗaya bi da bi. Ga kowane ƙimar tauri, kowanne yana auna daidai gwargwado 5

maki na ƙimar taurin Leeb a cikin kewaye da fiye da maɓallan uku waɗanda ke buƙatar taurin juyawa,

amfani da matsakaicin ƙimar lissafi na taurin Leeb da matsakaicin ƙimar taurin da ta dace azaman ƙimar daidaitawa

bi da bi, yi taurin kai na kowane mutum mai lanƙwasa mai bambanci. Lanƙwasa mai bambanci aƙalla ya kamata ya haɗa da ƙungiyoyi uku na

bayanai masu alaƙa.

| Nau'in Na'urar Tasiri | Nisa tsakanin tsakiyar lanƙwasa biyu | Nisa tsakanin tsakiyar maɓalli zuwa gefen samfurin |

| Ba ƙasa da (mm) | Ba ƙasa da (mm) | |

| D | 3 | 5 |

| DL | 3 | 5 |

| C | 2 | 4 |

5 Karanta Darajar da aka auna

Bayan kowace aikin tasiri, LCD ɗin zai nuna ƙimar da aka auna a halin yanzu, lokutan tasiri da ɗaya, mai kunna zai sanar da dogon ihu idan ƙimar da aka auna ba ta cikin madaidaicin kewayon ba. Lokacin da aka isa lokutan tasiri da aka riga aka saita, mai kunna zai sanar da dogon kuka. Bayan daƙiƙa 2, mai kunna zai sanar da ɗan gajeren kuka, kuma ya nuna matsakaicin ƙimar da aka auna.

Bayan an yi amfani da na'urar bugun sau 1000 zuwa 2000, da fatan za a yi amfani da goga nailan da aka bayar don tsaftace bututun jagora da jikin bugun. Bi waɗannan matakan yayin tsaftace bututun jagora,

1. warware zoben tallafi

2. cire jikin tasirin

3. Juya goga nailan a akasin agogon zuwa ƙasan bututun jagora sannan a fitar da shi sau 5

4. Shigar da jikin tasirin da zoben tallafi idan an kammala.

Saki jikin tasirin bayan amfani.

An haramta duk wani mai shafawa a cikin na'urar da ke aiki.