Lambar taurin ƙarfe ita ce H. Dangane da hanyoyin gwaji daban-daban na taurin, wakilcin gargajiya sun haɗa da Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), taurin Shore (HS), da sauransu, waɗanda daga cikinsu aka fi amfani da HB da HRC. HB yana da faffadan aikace-aikace, kuma HRC ya dace da kayan da ke da taurin saman, kamar taurin maganin zafi. Bambancin shine cewa indent na mai gwajin taurin ya bambanta. Mai gwajin taurin Brinell shine indent ball, yayin da mai gwajin taurin Rockwell shine indent na lu'u-lu'u.

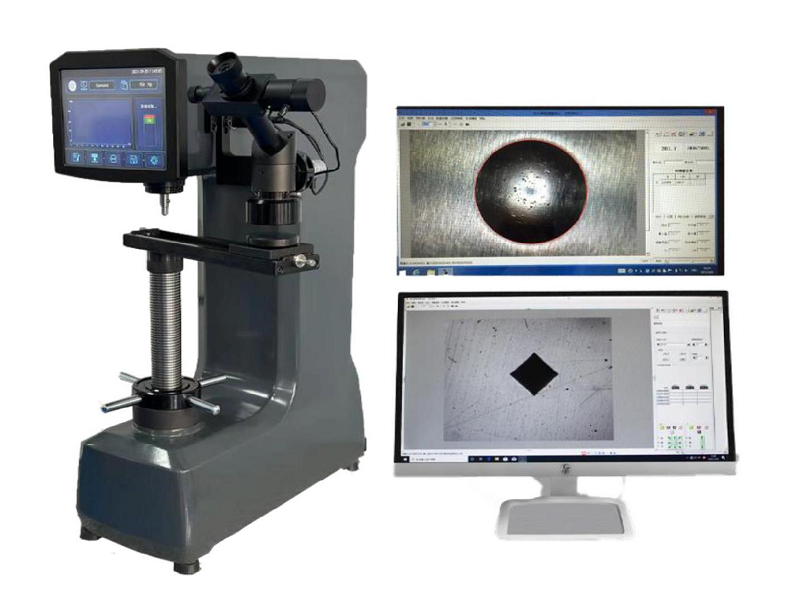

HV-ya dace da nazarin na'urar hangen nesa. Taurin Vickers (HV) Matse saman kayan da nauyinsa bai wuce kilogiram 120 ba da kuma mazugi mai siffar lu'u-lu'u mai kusurwar kusurwa na 136°. An raba yankin saman ramin shigar da kayan ta hanyar ƙimar kaya, wanda shine ƙimar taurin Vickers (HV). Ana bayyana taurin Vickers a matsayin HV (duba GB/T4340-1999), kuma yana auna samfuran da suka yi siriri sosai.

Na'urar gwajin taurin kai ta HL mai ɗaukar hoto ta dace da aunawa. Yana amfani da kan ƙwallon tasiri don yin tasiri ga saman taurin kai da kuma samar da tsalle. Ana ƙididdige taurin ta hanyar rabon saurin dawowa na naushi a 1mm daga saman samfurin zuwa saurin tasiri. Tsarin shine: Taurin Leeb HL = 1000×VB (gudun sake dawowa)/VA (gudun tasiri).

Ana iya canza na'urar gwajin taurin Leeb mai ɗaukuwa zuwa Brinell (HB), Rockwell (HRC), Vickers (HV), Shore (HS) bayan an auna Leeb (HL). Ko kuma a yi amfani da ƙa'idar Leeb don auna ƙimar taurin kai tsaye tare da Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS).

HB - Taurin Brinell:

Ana amfani da taurin Brinell (HB) gabaɗaya lokacin da kayan suka yi laushi, kamar ƙarfe marasa ƙarfe, ƙarfe kafin a yi amfani da shi a zafi ko bayan a yi amfani da shi a cikin annealing. Ana amfani da taurin Rockwell (HRC) gabaɗaya don kayan da ke da taurin da ya fi girma, kamar taurin bayan an yi amfani da shi a cikin zafi, da sauransu.

Taurin Brinell (HB) wani nau'in gwaji ne na wani girman. Ana matse ƙwallon ƙarfe mai tauri ko ƙwallon carbide mai wani diamita a saman ƙarfe don a gwada. Ana kiyaye nauyin gwajin na wani lokaci, sannan a cire nauyin don auna diamita na matsewar da ke kan saman da za a gwada. Ƙimar taurin Brinell ita ce ƙimar da aka samu ta hanyar raba nauyin ta hanyar yankin saman zagaye na matsewar. Gabaɗaya, ƙwallon ƙarfe mai tauri mai wani girman (yawanci diamita 10mm) ana matse shi a saman kayan tare da wani nauyi (yawanci 3000kg) kuma ana kiyaye shi na wani lokaci. Bayan an cire nauyin, rabon nauyin zuwa yankin matsewar shine ƙimar taurin Brinell (HB), kuma naúrar ita ce ƙarfin kilogram/mm2 (N/mm2).

Taurin Rockwell yana ƙayyade ma'aunin ƙimar taurin bisa ga zurfin nakasar filastik na na'urar. Ana amfani da 0.002 mm azaman na'urar taurin kai. Idan HB>450 ko samfurin ya yi ƙanƙanta, ba za a iya amfani da gwajin taurin Brinell ba kuma ana amfani da ma'aunin taurin Rockwell maimakon haka. Yana amfani da mazugi mai lu'u-lu'u mai kusurwar kusurwa na 120° ko ƙwallon ƙarfe mai diamita na 1.59 ko 3.18mm don matsawa zuwa saman kayan da aka gwada a ƙarƙashin wani kaya, kuma ana ƙididdige taurin kayan daga zurfin na'urar. Dangane da taurin kayan gwajin, ana bayyana shi a cikin ma'auni uku daban-daban:

HRA: Taurin da ake samu ta hanyar amfani da kaya mai nauyin kilogiram 60 da kuma ma'aunin lu'u-lu'u, wanda ake amfani da shi wajen yin kayan da ke da tauri sosai (kamar carbide mai siminti, da sauransu).

HRB: Ita ce taurin da ake samu ta hanyar amfani da nauyin kilogiram 100 da ƙwallon ƙarfe mai tauri mai diamita na 1.58mm, wanda ake amfani da shi don kayan da ke da ƙarancin tauri (kamar ƙarfe mai annealed, ƙarfe mai siminti, da sauransu).

HRC: Ita ce taurin da aka samu ta hanyar amfani da nauyin kilogiram 150 da kuma ma'aunin lu'u-lu'u, wanda ake amfani da shi don kayan da ke da tauri sosai (kamar ƙarfe mai tauri, da sauransu).

Bugu da ƙari:

1. HRC yana nufin sikelin taurin Rockwell C.

2. Ana amfani da HRC da HB sosai wajen samarwa.

3. Tsarin HRC mai dacewa HRC 20-67, daidai yake da HB225-650,

Idan taurin ya fi wannan kewayon, yi amfani da sikelin taurin Rockwell A HRA,

Idan taurin ya yi ƙasa da wannan kewayon, yi amfani da sikelin taurin Rockwell B na HRB,

Iyakar taurin Brinell mafi girma ita ce HB650, wanda ba zai iya zama mafi girma fiye da wannan ƙimar ba.

4. Ma'aunin ma'aunin ma'aunin taurin Rockwell C shine mazugi mai kusurwar kusurwa na digiri 120. Nauyin gwajin wani ƙima ne. Ma'aunin kasar Sin shine 150 kgf. Ma'aunin ma'aunin taurin Brinell shine ƙwallon ƙarfe mai tauri (HBS) ko ƙwallon carbide (HBW). Nauyin gwajin ya bambanta da diamita na ƙwallon, daga 3000 zuwa 31.25 kgf.

5. Shigar da taurin Rockwell ƙarami ne, kuma ƙimar da aka auna an tsara ta ne a wuri ɗaya. Ya zama dole a auna maki da yawa don nemo matsakaicin ƙimar. Ya dace da samfuran da aka gama da yanka siriri kuma an rarraba shi azaman gwajin da ba zai lalata ba. Shigar da taurin Brinell ya fi girma, ƙimar da aka auna daidai ne, bai dace da samfuran da aka gama da yanka siriri ba, kuma gabaɗaya ba a rarraba shi azaman gwajin da ba zai lalata ba.

6. Darajar taurin Rockwell lamba ce da ba a san sunanta ba ba tare da raka'a ba. (Saboda haka, ba daidai ba ne a kira taurin Rockwell a matsayin wani mataki.) Darajar taurin Brinell yana da raka'a kuma yana da alaƙa ta kusa da ƙarfin taurin.

7. Taurin Rockwell yana bayyana kai tsaye a kan na'urar bugawa ko kuma a nuna shi ta hanyar dijital. Yana da sauƙin aiki, sauri da fahimta, kuma ya dace da samar da taro. Taurin Brinell yana buƙatar na'urar hangen nesa don auna diamita na shigarwa, sannan duba teburin ko lissafi, wanda ya fi wahalar aiki.

8. A wasu sharuɗɗa, ana iya musanya HB da HRC ta hanyar duba teburin. Ana iya rubuta dabarar lissafin tunani kamar haka: 1HRC≈1/10HB.

Gwajin tauri hanya ce mai sauƙi kuma mai sauƙi ta gwaji a gwajin mallakar injiniya. Domin amfani da gwajin tauri don maye gurbin wasu gwaje-gwajen mallakar injiniya, ana buƙatar ingantacciyar alaƙa tsakanin tauri da ƙarfi a cikin samarwa.

Aiki ya tabbatar da cewa akwai kusan alaƙa mai dacewa tsakanin ƙimar tauri daban-daban na kayan ƙarfe da kuma tsakanin ƙimar tauri da ƙimar ƙarfi. Saboda ƙimar tauri ana ƙayyade ta ne ta hanyar juriyar tauri ta farko tauri ta filastik da kuma ci gaba da juriyar tauri tauri, ƙarfin kayan yana ƙaruwa, ƙarfin juriyar tauri ...

Lokacin Saƙo: Agusta-16-2024