1) Za a iya amfani da na'urar gwajin taurin Rockwell don gwada taurin bangon bututun ƙarfe?

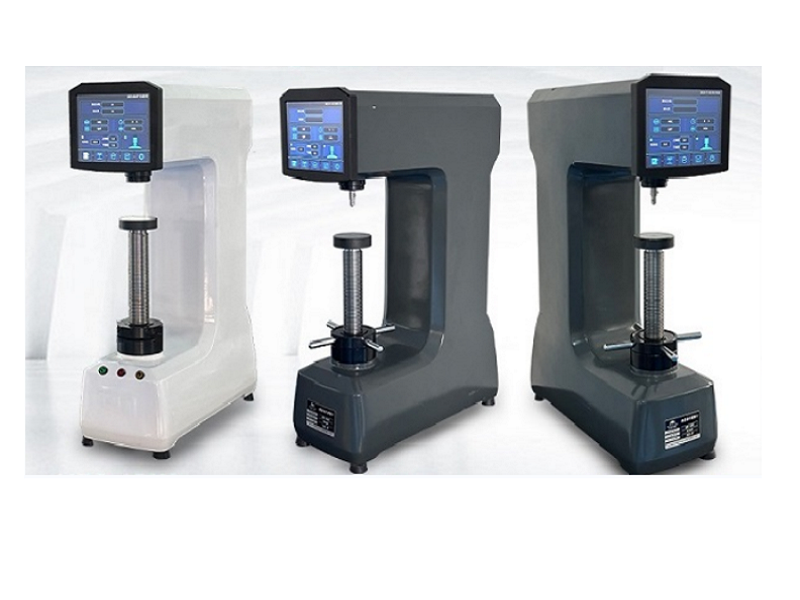

Kayan gwajin shine bututun ƙarfe na SA-213M T22 mai diamita na waje na 16mm da kauri na bango na 1.65mm. Sakamakon gwajin gwajin taurin Rockwell sune kamar haka: Bayan cire oxide da Layer ɗin da aka cire daga saman samfurin da niƙa, an sanya samfurin a kan teburin aiki mai siffar V kuma an yi gwajin taurin Rockwell kai tsaye a saman waje, ta amfani da na'urar gwajin taurin Rockwell ta HRS-150S ta dijital ta Rockwell a kan nauyin :980.7N.

Bayan gwajin, za a iya ganin cewa bututun ƙarfe da ke kan bango yana da ɗan canji, kuma sakamakon shine: ƙarancin ƙimar da aka auna taurin Rockwell ya sa gwajin ya zama ba shi da inganci.

A cewar GB/T 230.1-2018 « Gwajin Taurin Rockwell don kayan ƙarfe Sashe na 1: Hanyoyin gwaji », taurin Rockwell shine 80HRBW kuma mafi ƙarancin kauri na samfurin shine 1.5mm. Kauri na samfurin Lamba 1 shine 1.65mm, kauri na layin da aka cire shi shine 0.15~0.20mm, kuma kauri na samfurin bayan cire layin da aka cire shi shine 1.4~1.45mm, wanda yake kusa da mafi ƙarancin kauri na samfurin da aka ƙayyade a cikin GB/T 230.1-2018.

A lokacin gwajin, saboda ba a tallafawa cibiyar samfurin ba, zai haifar da nakasu mai sauƙi (mai yiwuwa ido ba ya gani), don haka ƙimar da aka auna taurin Rockwell ba ta da yawa.

2) Yadda ake zaɓar samanRockwellgwajin tauri don gwajin bututun ƙarfe:

Kamfaninmu ya gwada taurin saman bututun ƙarfe akai-akai kuma ya cimma waɗannan sakamakon:

Gwajin taurin Rockwell na sama ko gwajin taurin Rockwell a saman bututun ƙarfe mai sirara. Rashin isasshen tallafi na bango zai haifar da nakasar samfurin kuma ya haifar da ƙarancin sakamakon gwaji;

Idan aka sanya tallafin silinda a tsakiyar bututun ƙarfe mai bakin bango, saboda ba zai iya tabbatar da cewa axis na indenter da alkiblar ɗaukar kaya da kuma saman bututun ƙarfe a tsaye zuwa saman ba, da kuma saman waje na bututun ƙarfe da kuma can zai haifar da gibin tallafin silinda na gibin tsakanin saman zagaye na bututun ƙarfe da saman tallafi na silinda, zai kuma haifar da sakamakon gwajin ya yi ƙasa sosai.

Canza gwajin taurin Vickers zuwa gwajin taurin Rockwell bayan an goge samfurin bututun ƙarfe, zai sami ƙimar taurin Rockwell daidai.

2. Bayan cire layin oxide da decarburization akan saman bututun ƙarfe da kuma sarrafa jirgin gwaji a saman waje da kuma sanya shi a ciki, Value ya fi daidai idan aka kwatanta da na'urar gwajin tauri ta Superficial Rockwell tare da na'urar gwajin tauri ta Rockwell.

Lokacin Saƙo: Mayu-28-2024