Akwai nau'ikan rufin ƙarfe da yawa. Rufi daban-daban yana buƙatar ƙarfin gwaji daban-daban a gwajin ƙarfin microhardness, kuma ba za a iya amfani da ƙarfin gwaji ba bisa ga ka'ida ba. Madadin haka, ya kamata a gudanar da gwaje-gwajen daidai da ƙimar ƙarfin gwaji da ƙa'idodi suka ba da shawarar. A yau, za mu gabatar da gwajin taurin micro Vickers na rufin zinc ko rufin ƙarfe na zinc-aluminum-magnesium da aka shafa akan ƙarfe.

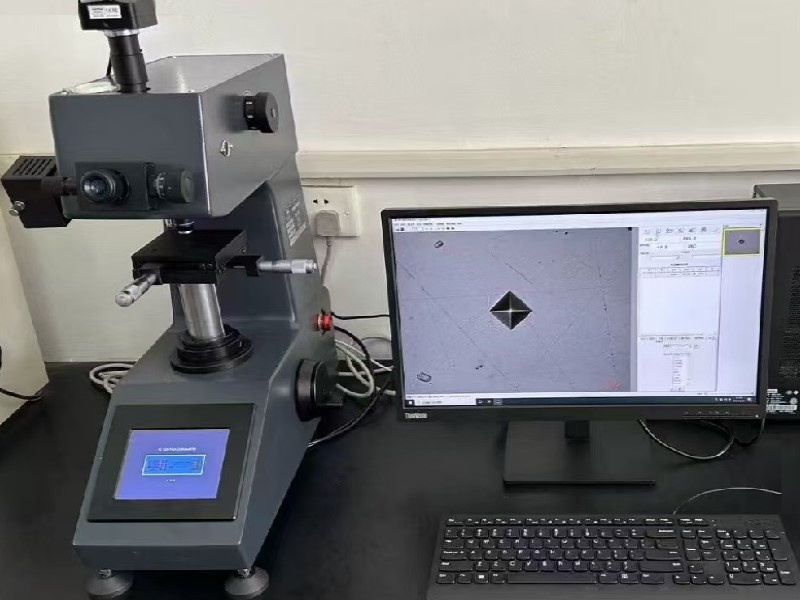

1. Shirya samfuran ƙarfe masu inganci na murfin zinc (ko murfin aluminum-magnesium) shine mataki na farko a gwajin murfin. Shirya samfuran murfin zinc ya ƙunshi matakai da yawa, gami da ɗaukar samfur, ɗorawa, da niƙawa da gogewa kafin a yi. Manufar shirya irin waɗannan samfuran ita ce a niƙa saman sashin aikin zuwa wani wuri mai santsi, mai faɗi wanda ke ba da damar ganin ramukan Vickers a sarari, yana sauƙaƙa auna ma'aunin ramuka don samun ƙimar tauri.

2. Don gwajin tauri na murfin zinc: tunda murfin zinc yana da kauri sosai, ana iya yin gwaje-gwajen tauri da ƙarfin gwaji daban-daban. A kan samfurin iri ɗaya, ƙaramin ƙarfin gwajin da aka yi amfani da shi, ƙaramin girman shigarwa; akasin haka, girman ƙarfin gwajin, girman shigarwa. Idan murfin da ke kewaye da shigarwar ya nuna alamun fashewa ko nakasa, ya kamata a zaɓi ƙaramin ƙarfin gwaji. Ana maimaita wannan tsari har sai murfin da ke kewaye da shigarwar Vickers ya kasance ba tare da nakasa ba - wannan matakin ƙarfin gwaji shine wanda ya dace da samfurin.

2.1 Kauri daban-daban na shafi ya yi daidai da takamaiman kewayon ƙarfin gwaji, wanda yake da mahimmanci don guje wa karkatar da sakamakon gwaji. Ga abin da ke tafe don zaɓin ƙarfin gwaji don rufin gama gari (rufe zinc, rufe chromium), wanda ya dace da masu gwajin taurin micro Vickers (HV):

| Nau'in Shafi | Shafi Kauri (μm) | Ba da shawara Ƙarfin Gwaji (gf) | Mai dacewa Sikelin HV | Muhimman Kariya |

| Sintiki Faranti | 5 ~ 15 | 25 ~ 50 | HV0.025, HV0.05 | Rufin zinc yana da laushi sosai (yawanci HV50 ~ 150); ƙaramin ƙarfi yana hana shiga cikin ruwa fiye da kima. |

| Sintiki Faranti | 15 ~ 50 | 50 ~ 100 | HV0.05, HV0.1 | Yayin da kauri ke ƙaruwa, ana iya ɗaga ƙarfi yadda ya kamata don tabbatar da cewa gefuna sun bayyana. |

| Chromium Faranti | 1 ~ 5 | 10 ~ 25 | HV0.01, HV0.025 | Chromium mai tauri (HV800~1200) yana da tauri mai yawa; ƙaramin ƙarfi yana hana lalacewar inter. |

| Chromium Faranti | 5 ~ 20 | 25 ~ 100 | HV0.025, HV0.1 | Lokacin da kauri ya kai ⼞10μm, HV0.1force yana daidaita daidaito da inganci. |

| Haɗaɗɗen abu Shafi | <5 | ≤25 | HV0.01, HV0.025 | Ga masu shafa kamar zinc-nickel alloy da chromium-nickel alloy, a hana shigar da ruwa daga shiga cikin murfin sosai. |

2.2 Sauran Muhimman Abubuwan Da Ke Tasiri

Baya ga kauri, waɗannan abubuwa biyu za su ƙara inganta zaɓin ƙarfin gwaji, kuma suna buƙatar yin hukunci bisa ga ainihin yanayin:

Range na Taurin Shafi:

Rufin da ke da laushi (misali, farantin zinc, HV < 200): Idan ƙarfin gwajin ya yi ƙanƙanta, ƙofofin da ke ciki na iya yin duhu saboda nakasar filastik na rufin. Ana ba da shawarar zaɓar iyakar sama ta kewayon da aka ba da shawarar (misali., kauri 10 μm, zaɓi ƙarfin gwaji 50gf).

Rufin da ke da tauri (misali, chromium plating, HV > 800): Babban tauri yana haifar da ƙananan ramuka, don haka ƙarfin gwajin bai kamata ya yi ƙanƙanta ba (kamar, kauri 5 μm, zaɓi ƙarfin gwaji 25gf) don hana kuskuren aunawa na diagonal na shigarwar ya wuce ±5%.

2.3 Bukatun Ma'auni da Bayanai

Masana'antu daban-daban suna da ƙa'idodi bayyanannu. Misali:

Masana'antar kera motoci galibi tana amfani da ISO 14577 (Gwajin Shigar da Kayan Aiki), wanda ke ba da damar daidaita ƙimar ƙarfi gwargwadon kauri na rufi;

Masana'antu gabaɗaya suna nufin ASTM E384, wanda ke buƙatar cewa diagonal na indentation shine ≤ 1/2 na kauri na shafi da kuma ≥ sau 10 radius na indent tip (don guje wa tasirin tip).

A ƙarshe, zaɓin ƙarfin gwaji don gwajin taurin micro-Vickers na rufin ƙarfe zai bi manufar "kauri da farko, daidaita taurin, da garantin yau da kullun":

Da farko, ƙayyade kewayon ƙarfin gwajin bisa ga kauri na shafi (duba teburin da ke sama);

Daidaita ƙimar ƙarfi bisa ga taurin murfin (zaɓi iyaka ta sama don rufin laushi da ƙasan iyaka don rufin tauri);

A ƙarshe, daidaita da ƙa'idodin masana'antu (kamar ISO 14577 da ASTM E384) don tabbatar da ingancin sakamakon gwaji.

Lokacin Saƙo: Satumba-03-2025