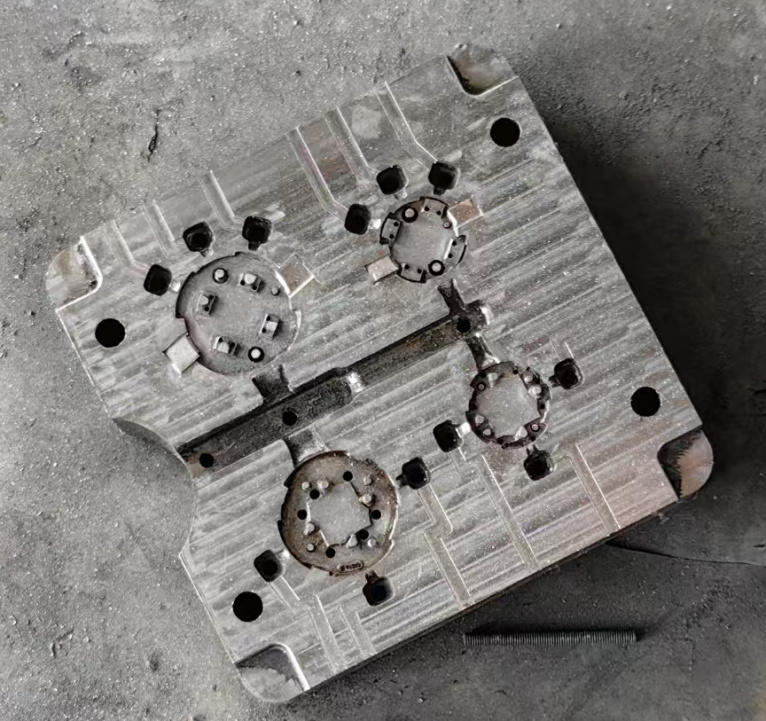

Kamar yadda muka sani, kowace hanyar gwajin tauri, ko Brinell, Rockwell, Vickers ko na'urar gwajin tauri ta Leeb mai ɗaukuwa, tana da iyakokinta kuma ba ta da iko a kan komai. Ga manyan kayan aikin geometric masu nauyi da rashin tsari kamar wanda aka nuna a cikin misalin da ke ƙasa, yawancin hanyoyin gwaji na yanzu suna amfani da na'urorin gwajin tauri ta Leeb mai ɗaukuwa don sarrafa taurinsu.

Hanyar auna ƙarfin aiki ta na'urar gwajin taurin Leeb tana da abubuwa da yawa da ke shafar daidaiton taurinsa: kamar: modulus na roba na abu, amfani da kan ƙwallon, ƙaiƙayin saman aiki, radius mai lanƙwasa, zurfin saman da aka taurare, da sauransu. Idan aka kwatanta da hanyoyin aunawa marasa motsi na Brinell, Rockwell da Vickers, kuskuren ya fi girma. Idan taurin yana buƙatar daidaito mafi girma, ta yaya za mu zaɓi na'urar gwada taurin?

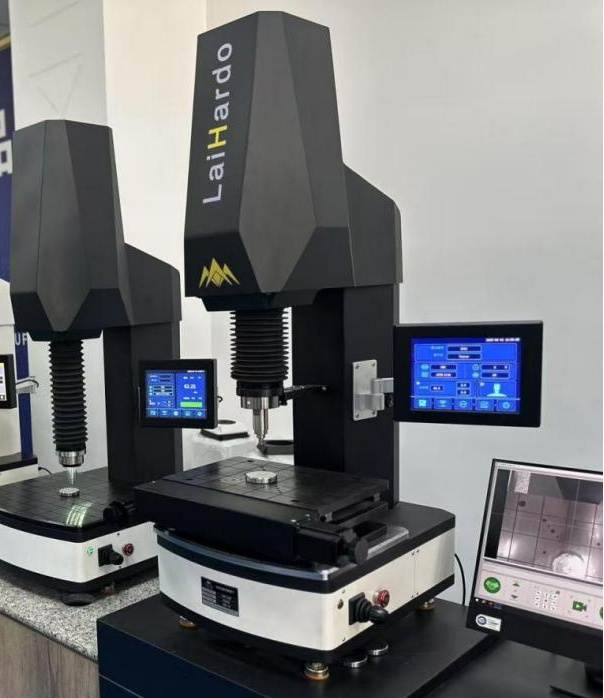

Wannan nau'in kayan aiki mai nauyi a cikin tsarin gwajin taurin kai na yau da kullun, kafin a ɗora da sauke na'urar gwajin taurin kai, da kuma sauke na'urar gwajin taurin kai zai kawo babban aiki a cikin tsarin aiki, to ta yaya za mu zaɓi na'urar gwajin taurin kai? Mai zuwa yana ba da shawarar amfani da na'urar gwajin taurin kai tare da tsarin ɗaga kai don kammala dukkan tsarin gwajin. Kamar yadda aka nuna a ƙasa:

Wannan maganin gwajin tauri zai iya cimma gwajin tauri na Rockwell/Vickers da Brinell bisa ga ƙa'idodin gwajin tauri (GB/T 231.1, GB/T 4340.1, ISO6507, ISO6508, ASTM E18, da sauransu), kuma ya cika buƙatun gwaji mai inganci da ingantaccen samarwa na kayan aiki masu nauyi.

Na'urar gwajin taurin ɗaga kai ta atomatik tana da benci mai tsayayye, wanda ke rage kuskuren da sukurori da ɗaga bencin aiki ke haifarwa zuwa ga daidaiton ma'aunin tauri. Bencin aiki yana da girma kuma yana iya ɗaukar manyan kayan aikin auna nauyi. Ma'aunin maɓalli ɗaya yana rage kuskuren gwaji da aikin mai gwajin sosai, wanda ya dace kuma mai sauri.

Lokacin Saƙo: Afrilu-23-2025